G2050

Protecting Private Drinking Water Supplies:

Water Well Location, Construction, Condition, and Management

This publication is one of six in a series (Figure 1) designed to help rural families protect their private drinking water supplies. The greatest protection of drinking water supplies can be achieved by applying principles from all publications in the series.

Sharon O. Skipton, Extension Water Quality Educator

Jan R. Hygnstrom, Extension Project Manager

Wayne Woldt, Extension Water and Environment Specialist

|

Nearly all rural families rely on groundwater from a water well for their drinking water. Safe guarding the drinking water depends on the placement of the well on the site, how the well was constructed, how the well is maintained, the location of new wells, and managing wells no longer in use. Working with a Nebraska-licensed professional to carefully manage the drinking water well, and all other wells on the site, will help keep the groundwater that supplies drinking water safe.

Begin by completing the following assessment.

Information about the well should have been recorded when the well was constructed. You may have a copy of this information. The licensed well driller who constructed the well also may have a copy. In addition, drinking water wells constructed after September 1993 were required to be registered with the Nebraska Department of Natural Resources (NDNR). If your well was constructed after that date, contact the NDNR for a copy of the well’s registration information.

Using this information, respond to the following statements. Make a check mark beside those statements that accurately describe your drinking water well. Unchecked statements indicate factors associated with your drinking water well location, construction, condition, or management that could put your drinking water supply at risk of contamination. Although voluntary, risk factors should be addressed. Work with a licensed professional to attempt to eliminate risk factors when possible. Following the assessment is additional information on each of the topic areas, to help you understand the associated risks.

Well Location

| ____ | Well is upslope from all pollution sources, with no surface water runoff from these reaching the well. |

| ____ | Well is 50 feet or more from septic tank and 100 feet or more from septic system drainfield. |

| ____ | Well is 100 feet or more from any other known or suspected source of pollution, such as chemical or fuel storage and handling areas. |

Well Construction and Condition

| ____ | Well casing (steel or plastic pipe portion of well) has no holes or cracks. |

| ____ | Well casing depth extends below the water level in the well and more than 20 feet below grade. |

| ____ | Well annular space (space between the outside of the casing and sides of the hole) is sealed with grout. |

| ____ | Well casing height is at least 12 inches above grade. |

| ____ | Watertight well cap is firmly installed. |

| ____ | Well is drilled and meets drinking water well construction standards. |

Well Management

| ____ | Anti-backflow devices are installed on all faucets that have hose connections. |

| ____ | Annual water testing is conducted for bacteria and nitrate and other suspected contaminants; reports indicate satisfactory quality. |

| ____ | No known inactive, unused water wells are at the homesite. |

| ____ | Well mechanics and condition are inspected periodically by a Nebraska-licensed water well contractor or pump installation contractor. |

Well Location

|

||||||||

Constructing a well in a safe place takes careful planning and consideration of factors such as where the well is in relation to surface drainage and groundwater flow. A well downhill from pollution sources runs a greater risk of contamination from surface drainage than a well on the uphill side of pollution sources.

Surface slope does not always indicate the direction groundwater might move. In shallow aquifers, groundwater flow is often in the same direction as surface water flow. If the aquifer supplying water to the well is far below the surface, the direction of groundwater flow may be different from that on the land surface.

Good well location is encouraged by requiring minimum separation distances from sources of potential pollution, thus using the natural protection provided by filtration through soil. Table I lists required minimum separation distances from specific pollution sources for new well installation.

When no distances are specified for a possible source of pollution such as pesticide mixing pads, provide as much separation as possible between the well and any potential contamination source — especially if the site is on highly permeable soils of river valleys or wet meadows. The licensed professional installing the well can provide suggestions based on knowledge of requirements and geological conditions.

Separating a well from contamination sources may reduce the chance of pollution, but it does not guarantee that the well will be safe. Runoff and shallow groundwater can carry contaminants from one place to another. Wells located in the path of polluted water run a risk of contamination from overland flow washing into an improperly constructed and sealed well.

Well Construction and Condition

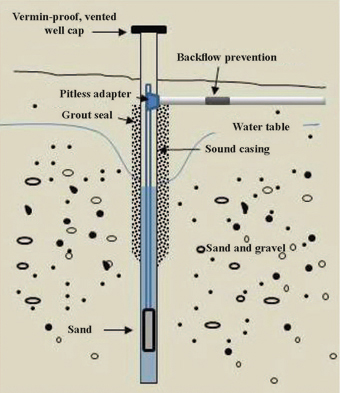

Poor well design can allow groundwater contamination by allowing contaminated rain or melted snow to reach the water table without filtering through soil. Proper well design reduces the risk of pollution by sealing the well from contaminants that might enter it from the surface. Figure 2 illustrates the typical well installation to meet construction regulations.

Casing, Grouting, and Well Cap

The licensed professional inserts a well casing (steel or plastic pipe) into a drilled hole during construction. The annular space (space between the casing and the sides of the hole) is a direct channel for surface water and pollutants to reach groundwater. To seal off that channel, the annular space is filled with grout — cement, concrete, or a special type of clay called bentonite. Both grout and casing prevent pollutants from seeping into the well. If the casing can be moved around by pushing against it, there may be no seal in the annular space to keep out contaminants. To prevent contaminants from flowing down inside of the well casing, a watertight, sanitary well cap is firmly installed. Check the well cap to see that it is in place and tightly secured. If your well has a vent, be sure that it still faces the ground, is tightly connected to the well cap or seal, and remains properly screened.

|

Casing Depth and Height

Casing depth and height will vary and are somewhat dependent on the geological formation into which the well is being drilled. A licensed professional will be able to recommend depths for the area in which a well is being constructed. In general, deeper-cased wells (extending 30 feet or more below the water level in the well) can provide greater protection. Consult your licensed professional for recommendations in your area.

Typically, the casing extends 1 to 2 feet above surrounding land, preventing surface water from running down the casing or over the cap and into the well.

Well Age

Well construction techniques have evolved and improved over time. Thus, newer well construction methods provide greater protection of water quality than those used for old wells. In addition, older wells are more likely to have thinner casing that could have corroded over time and older well pumps are more likely to leak lubricating oils, which can get into the well.

In 1965, the Nebraska Well Drillers Association and the University of Nebraska Conservation and Survey Division developed minimum standards for private water well construction. These standards were revised in cooperation with the State of Nebraska in 1972 and again in 1981. In 1988, the State of Nebraska adopted regulations to implement the Water Well Standards and Contractors’ Licensing Act to regulate the installation of water wells. Regulations have been revised as new scientific information has become available.

Well Type

Historically, dug wells were holes usually more than 2 feet in diameter, often constructed by hand and cased with brick, tile, or stone materials that did not always form or maintain a watertight barrier. Modern well construction methods allow a contractor to install a dug well using gravel packed concrete tile, slotted fiberglass, or PVC casing, with grouted watertight casing in the top 10 feet to improve protection from surface contamination. Improperly constructed dug wells pose a risk of contaminating the drinking water supply. Driven-point (sand point) wells were constructed by driving assembled lengths of pipe into the ground. These wells were normally smaller in diameter (2 inches or less) and less than 50 feet deep. Driven-point wells pose a risk of allowing contaminants to enter drinking water supplies. The construction of driven-point wells for drinking water purposes is prohibited under current Nebraska well regulations. Drilled wells are the most common type of well used today for drinking water purposes.

Drilled wells used for drinking water supply are commonly 4-8 inches in diameter. Their construction is regulated under Title 178 Chapter 12 – Regulations Governing Water Well Construction, Pump Installation, and Water Abandonment Standards (Nebraska Department of Health and Human Services). Drinking water wells installed by licensed professionals following current regulations provide the greatest protection to drinking water supplies.

Well Depth

Shallow wells draw from groundwater nearest the land surface, which may be directly affected by activities in the area. Areas with sand and gravel are particularly vulnerable. Deep wells (with the water table depth greater than 100 feet) provide more protection than shallower wells.

Well Management

Wells require good management, including having the water tested every year for bacteria and nitrate, keeping the well area clean and accessible, keeping pollutants as far away as possible, and periodically having a qualified Nebraska-licensed water well contractor or pump installation contractor check the well mechanics and physical condition.

Existing wells were most likely sited and constructed according to traditional practices or regulations in place at the time of construction. Consider how closely an existing well conforms to current standards, which incorporate new knowledge about groundwater contamination and well water. If needed, have a licensed professional reduce risks to your drinking water by eliminating a well pit, installing or repairing a cap, extending or repairing existing casing, installing new casing, grouting an open annular space, or making other needed repairs or modifications to the system.

Backflow Prevention

Backflow can allow contaminants to flow back into the well through a hose. Use an anti-backflow device when filling containers to prevent chemical mixtures from flowing back into the well and contaminating groundwater. If there is no such device, keep the hose out of the container to maintain an air gap when filling.

Water Testing

The safety and quality of private drinking water in Nebraska is not subject to any federal or state regulation, and is at the discretion of the water user except in cases where water quality is regulated at the local level or when state licensing may be required for a specific activity such as operating a child care facility. Lending agencies may require a private water supply to meet federal nitrate and bacteria standards for public water supplies prior to approving a real estate loan. In most cases, the well also must meet current state construction and location standards before a loan will be approved.

Although not required by federal or state regulations, testing a private water supply is a good idea. It is not practical to have private drinking water tested for every conceivable pollutant. A good initial set of tests for a private well might include bacteria, nitrate, total dissolved solids, hardness, pH, and conductivity. Testing for other contaminants may be important if specific problems are suspected. A broad scan of the water quality for a number of contaminants such as metals, inorganic chemicals, volatile organic chemicals, and pesticides is another option for consideration.

Generally, private drinking water should continue to be tested annually for bacteria and nitrate contamination. Tests for nitrate and bacteria do not guarantee the water is safe, as other contaminants could be present. Additional testing should be considered for any existing or newly suspected contaminants.

Unused Wells

Many sites have old, unused wells in a poor state of repair. Any inactive water well in a poor state of repair is considered an illegal water well. If not properly filled and sealed, these water wells can provide a direct route for surface water that may be carrying contaminants to groundwater. Hire a Nebraska-licensed water well contractor or pump installation contractor to close these wells. Cost sharing is available through many Natural Resources District (NRD) offices. Check local offices for information and qualifications.

Acknowledgments

This series of publications is the result of a collaborative effort between the University of Nebraska–Lincoln Extension, the Nebraska Department of Health and Human Services, the Nebraska Department of Environmental Quality, the Nebraska Well Drillers Association, and the Nebraska On-site Waste Water Association, all of whom place a high priority on protecting Nebraska’s drinking water resources.

This publication was modified from the University of Nebraska–Lincoln Extension publication EC98-766, Farm*A*Syst: Drinking Water Well Condition, and EC98-765, Farm*A*Syst: Improving Drinking Water Well Condition, which were adapted from material prepared for the Wisconsin and Minnesota Farm*A*Syst programs.

Partial funding was provided by the Nebraska Well Drillers Association, the Nebraska On-site Waste Water Association, and the Water Well Standards and Contractors’ Licensing Board.

This publication has been peer reviewed.

Visit the University of Nebraska–Lincoln Extension Publications Web site for more publications.

Index: Water Management

Drinking Water

Issued March 2011