G2044

Calibration of Sprayers (Also Seeders)

Methods and calculations for calibrating sprayers and seeders for accurate in-field application plus a section on converting weights and measures.

Robert N. Klein, Western Nebraska Crops Specialist

Applying the correct rate of a product is an important part of obtaining good results with both seeders and pesti- cide sprayers. With seeders too little seed reduces crop yields and increases weeds while too much seed increases costs and may reduce yields. With a pesticide application, too little product can mean poor control, while too much can mean crop injury, extra costs, and possible residue on the crop and/or carryover.

Many methods can be used to calibrate sprayers, including the ounce calibration and formula-based methods. With the ounce calibration method, 1/128 of an acre is sprayed and the spray is collected. When measured in ounces, the amount collected would be equal to the number of gallons applied per acre since there are 128 ounces in a gallon. (For further information on this method, see UNL Extension NebGuide Fine-Tuning a Sprayer with the “Ounce” Calibration Method, G1756.) Other methods involve using formulas which need to be remembered or recorded for easy use. These methods also may require converting some of the information you have.

The methods discussed in this NebGuide are simple relationships and do not require remembering formulas. However, you do need a general understanding of cross multiplication. The important thing is to be consistent: If you put an item on top of an equation on one side, the same item also goes on the top on the other side.

Factors Affecting Rates

Three factors determine sprayer application rate:

1. Speed

2. Nozzle spacing

3. Nozzle output (determined by orifice size, pressure, and density of spray solution)

Where:

Speed = Length or distance covered divided by time

Nozzle spacing = Width

Nozzle output = The quantity applied/unit time

The following diagram shows how these three factors are related:

| Speed = length or distance covered divided by time | ||

| Nozzle spacing (width) |

|

For example, to determine speed:

1 mile per hour (mph) is:

1 mile (5,280 ft) in 1 hour (60 minutes)

| Or 1 mph = | 5,280 ft/hour |

= 88 ft/min |

60 min/hour |

Problem 1. Determine speed in mph.

If we travel 440 feet (ft) in 30 seconds (sec), what is our speed in mph?

The objective is to determine the distance traveled in 60 seconds (1 minute) and divide by 88 (88 feet/minute is equal to 1 mph).

| for | 30 sec |

60 sec |

(D is the distance we are solving |

|

= |

||||

440 ft |

D |

We cross multiply to find the value of D

30 D = 60 x 440

30 D = 26,400

D |

= |

26,400 |

30 |

D = 880 ft/60 sec

Since every 88 ft traveled/60 sec (1 min) is equal to 1 mph, we divide 880 by 88 to get 10 mph.

Problem 2. Determine speed in mph.

If we travel 297 feet in 27 seconds, what is our speed?

27 sec |

60 sec |

|

= |

||

297 ft |

D |

27 D = 60 x 297

27 D = 17,820

D |

= |

17,820 |

27 |

D = 660 ft/60 sec

Divide by 88 since 1 mph = 88 ft/60 sec (1 min)

660 |

= |

7.5 mph |

88 |

Problem 3. Determine speed in mph.

If we travel 660 feet in 1 minute and 15 seconds, what is our speed?

First, convert 1 minute and 15 seconds to seconds: 60 + 15 = 75 seconds

75 (sec) |

= |

60 (sec) |

660 (ft) |

D |

75 D = D = |

39,600 528 ft/60 sec |

Divide by 88 since 1 mph = 88 ft/60 sec (1 min)

528 |

= |

6 mph |

88 |

Problem 4. Determine rate/acre.

If the sprayer is moving at 6 mph, the distance covered in one minute is 528 feet (6 mph x 88 ft/min = 528 feet).

To determine the area you cover with one nozzle in one minute if your sprayer has a 30-inch nozzle spacing:

Distance traveled 6 x 88 = 528 ft/min |

| 30 in (2.5 ft) |

Area sprayed = 1,320 sq ft (2.5 ft x 528 ft/min) |

Collect the output of several nozzles and determine the average output per nozzle. All nozzles should be within 10 percent of the manufacturer’s rating for that nozzle. For example an XR11003 delivers 0.3 gpm at 40 psi. If it delivers more than 0.33 gpm or 42.24 (128 x .33) ounces/min at 40 psi, the nozzle should be replaced. Any nozzle delivering 5 percent above or below the average delivery rate for all the nozzles should be replaced.

For this example, the average nozzle output is 32 oz per minute

or 32 (oz/min) ÷ 128 (oz/gallon) = 0.25 gpm

What is the rate per acre? One way to calculate application rate without remembering a formula is to use a relationship: The amount applied and the area sprayed per minute are the same as the amount applied and the area sprayed per acre. R = gal/acre

Minute Box |

Acre Box |

||||

Distance 6 x 88 = 528 ft |

|||||

| Nozzle Spacing 30 in ÷ 12 = 2.5 ft |

|

= |

|

||

528 x 2.5 = 1320 sq ft |

43,560 sq ft |

| From minute box | 0.25 |

= |

R |

From acre box |

1320 |

43,560 |

1320R = 10,890 (0.25 x 43,560)

R = 8.25 gal/acre

Problem 5. Determine the acres sprayed per minute.

Travel distance in one minute = 616 ft

Nozzle spacing = 30 in (20 nozzles on sprayer)

Nozzle output = 64 oz/minute

| What is travel speed? | 616 ÷ 88 = 7 mph (Remember 88 ft/min = 1 mph) |

| What is sprayer width? | 20 nozzles x 2.5 ft (30-inch spacing) per nozzle = 50 ft |

| What is application rate? | 64 oz/min |

= |

0.5 gpm |

128 oz/gal |

Minute Box |

Acre Box |

||||

Distance 616 ft |

|||||

| 30-inch nozzle spacing (2.5 ft) |

|

= |

|

||

1,540 sq ft |

43,560 sq ft |

0.5 |

= |

R |

1,540 |

43,560 |

|

| 1540 R | = |

21,780 |

| R | = |

14.14 gal/acre |

To determine the area covered by the sprayer in one minute:

1,540 sq ft/nozzle/minute

20 nozzles

1,540 x 20 ÷ 43,560 sq ft/acre = 0.71 acre/minute

Problem 6. Determine nozzle size needed to achieve the operational goal.

Sprayer speed = 7 mph

Nozzle spacing = 20 inches

Application rate desired = 17 gpa

Nozzle flow rate = F

Minute Box |

Acre Box |

|||||||||

7 x 88 = 616 ft |

||||||||||

Nozzle Spacing

|

|

= |

|

|||||||

1,029 sq ft |

43,560 sq ft |

F |

=

|

17

43,560

|

1,029 |

| 43,560 F | = | 17,493 |

| F | = | 0.40 gpm or XR8004* at 40 psi |

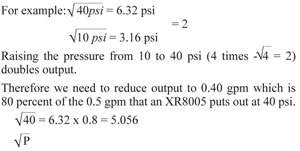

If we need 0.40 gpm, by design an XR8005* will give 0.5 gpm at 40 psi. Output varies by the square root of the pressure.

To solve for “P” take the result multiplied by itself.

5.056 x 5.056 = 25.6 psi

an XR8005 at 25.6 psi will give you 0.40 gpm

*Selected from TeeJet Nozzle Booklet by Spraying Systems.

Problem 7. Calibrate a hand sprayer.

First fill sprayer with water to a known level, a mark you can later refill to accurately. (Tip: It’s best to spray a test area over concrete so you can see the evenness of application.)

Spray test area |

100 sq ft = 10 ft x 10 ft | |

or |

250 sq ft = 10 ft x 25 ft | |

or |

500 sq ft = 10 ft x 50 ft or 20 ft x 25 ft |

Refill sprayer to same level as before, measuring amount of water it takes to refill sprayer.

If the pesticide recommendation is for 2 liquid ounces of product per 1,000 sq ft, the amount to include per 1,000 sq ft would be 1/4 cup or 4 tablespoons or 12 teaspoons. (See Weights and Measures Conversions on page 4.)

If during the test, 28 oz of water were applied over 250 sq ft, how much water and pesticide should be added to a 3-gallon sprayer?

| The amount of water you applied in | 28 oz |

V for volume |

How much water you will apply per test area 1,000 sq ft | ||

= |

|||||

250 sq ft |

1,000 sq ft |

250 V |

= |

28,000 |

V |

= |

112 ounces or ÷ 32 (oz/qt) = |

| 3.5 qt of water per 1,000 sq ft | ||

This indicates that 2 oz of pesticide should be added for every 3.5 qt of sprayer capacity.

With a 3-gallon sprayer, 12 qt (3 x 4 qt/gal) of water should be added to the sprayer tank.

2 oz |

P for Pesticide |

|

= |

||

3.5 qt |

12 qt |

3.5 P |

= |

24 |

P |

= |

6.86 oz or 0.86 cup (8 oz/cup) |

| 6.86/8 = 0.86 cup | This is the amount of pesticide to add to a 3-gallon sprayer |

Problem 8. Determine the density of spray solution.

The rate at which a fluid flows through a spray orifice varies with its density. Since all the tabulations are based on spraying water, which weighs 8.34 lb per U.S. gallon, conversion factors must be used when spraying solutions which are heavier or lighter than water. To determine the proper size nozzle for the solution to be sprayed, first multiply the desired GPM or GPA of solution by the water rate conversion factor. The conversion factors are the square root of specific gravity. (See Weights and Measures Conversion chart on page 4 for some common fertilizers.)

For example, the specific gravity of 28% nitrogen, which weighs 10.65 lb/gal, is:

10.65 (Wt of 28-0-0/gal) |

= |

1.28 specific gravity |

8.34 (Wt of water/gal) |

Conversion factor for 28-0-0 fertilizer or 28% nitrogen is

![]()

Weight of Solution |

Specific Gravity |

Conversion Factors |

| 7.0 lb per gallon | 0.84 |

0.92 |

| 8.0 lb per gallon | 0.96 |

0.98 |

| 8.34 lb per gallon - water | 1.00 |

1.00 |

| 9.0 lb per gallon | 1.08 |

1.04 |

| 10.0 lb per gallon | 1.20 |

1.10 |

| 10.65 lb per gallon - 28% nitrogen | 1.28 |

1.13 |

| 11.0 lb per gallon | 1.32 |

1.15 |

| 11.06 lb per gallon - 32% nitrogen | 1.33 |

1.15 |

| 12.0 lb per gallon | 1.44 |

1.20 |

| 14.0 lb per gallon | 1.68 |

1.30 |

Example of using the conversion factor:

Desired application rate is 20 GPA of 28% N.

GPA (solution) x Conversion factor = GPA (water)

20 GPA (28%) x 1.13 = 22.6 GPA (water)A nozzle size should be selected to supply 22.6 GPA of water at the desired pressure, speed, and nozzle spacing.

Problem 9. Determine the density of a spray solution.

In this example, the following has been recommended for an ecofallow corn field:

75 lb of nitrogen from 28% UAN

Density of 28% N = 10.65 lb/gal

10.65 x .28 = 2.982 lb N/gal

75 lb N |

= |

25.15 gal of 28% solution |

2.982 lb N/gal |

| Ingredient | Amount | Gallons |

| 28% Nitrogen | 75 lb N | 25.151 |

| Balance Pro | 2.0 oz | 0.016 |

| Fultime | 2.25 qt | 0.563 |

| Gramoxone Extra | 2 pt | 0.250 |

| Crop Oil Concentrate | 1 qt | 0.250 |

| 2,4-D 6 LVE | 1/2 pt | 0.063 |

| 26.293 or 26.3 gal/acre |

To determine how this will spray out and what gallonage of water is needed to get 26.3 gal/acre of this spray solution, three steps are required:

1. To determine specific gravity weigh an equal amount of the spray solution and an equal amount of water.

S.S. |

Water |

|

13.08 lb |

10.3 lb |

To determine specific gravity weight of spray solution:

13.08 lb (wt of spray solution) |

= |

1.27 specific gravity |

10.3 (wt of water) |

2. Determine conversion factor ![]()

3. Determine the quantity of water to calibrate sprayer:

Spray Rate x Conversion Factor = Water Amount Equivalent

26.3 gal/acre x 1.13 = 29.6 gal/acre

Now you need to calibrate the equipment to apply 29.6 gal/acre of water.

Problem 10. Calibrate a seeder.

How may pounds of seed are needed to plant 18 seeds/ft in a row with 10-inch spacing. Seed size is 15,000 seeds/lb and seed is collected for 500 ft.

To determine pounds of seed needed per acre:

12 in/ft |

= |

1.2 1.2 x 43,560 sq ft/acre = 52,272 ft of row/acre |

10 in/row |

52,272 x 18 seeds/ft row = 940,896 seeds/acre ÷ 15,000 seeds/lb = 62.7 lb/acre

Determine area seeded with one opener on one acre:

Test Box |

Acre Box |

|||||||||

| 10 inches per row or | ||||||||||

500 ft long |

||||||||||

|

|

= |

|

|||||||

415 sq ft (500 x .83) |

43,560 sq ft |

Then cross multiply:

Wt |

62.7 |

|

= |

||

415 |

43,560 |

43,560 Wt |

= |

26,020.5 (62.7 x 415) |

Wt |

= |

0.6 lb/opener or 9.6 oz/opener |

Weights and Measures Conversion

Weight

16 ounces = 1 lb = 453.6 grams

1 gallon water = 8.34 lb = 3.78 liters

1 short ton = 2,000 lb

1 long ton = 2,240 lb

1 cubic foot water = 62.4 lb

Liquid Measure

1 fluid ounce = 2 tablespoons = 29.57 milliliters

1 tablespoon = 3 teaspoons = 14.79 milliliters

1 cup = 16 T = 8 oz = 236.583 milliliters

16 fluid ounces = 1 pint = 2 cups

8 pints = 4 quarts = 1 gallon

Dry Measure

1 ounce = 28.3495 grams

Length

1 inch = 2.54 centimeters

3 feet = 1 yard = 91.44 centimeters

16.5 feet = 1 rod

5,280 feet = 1 mile = 1.61 kilometers

320 rods = 1 mile

Area

9 square feet = 1 square yard

43,560 square feet = 1 acre = 160 square rods

1 acre = 0.405 hectare

640 acres = 1 square mile

1 hectare = 2.47 acres

Speed

88 feet per minute = 1 mph

1 mph = 1.61 km/hour

1 mph = 0.477 meter/second

Volume

27 cubic feet = 1 cubic yard

1 cubic foot = 1,728 cubic inches = 7.48 gallons

1 gallon = 231 cubic inches

1 cubic foot = 0.028 cubic meters

Volume of sphere = D3 x 0.5236

Common Abbreviations and Terms Used

GPM = gallons per minute

GPA = gallons per acre

psi = pounds per square inch

mph = miles per hour

RPM = revolutions per minute

GPH = gallons per hour

FPM = feet per minute

T = tablespoon

t = teaspoon

Circles

Diameter x 3.1416 = circumference

Radius2 x 3.1416 = area

Spraying Systems Droplet Size in Microns

Very Fine = 153 and less

Fine = 154 - 241

Medium = 242 - 358

Coarse = 359 - 451

Very coarse = 452 - 740

Extensively coarse = 741 +

Fertilizer Facts

Pounds per gallon of liquid fertilizer at 60°F

| 10-34-0 | 11.40 |

| 11-37-0 | 11.60 |

| 7-21-7 | 11.00 |

| 28-0-0 | 10.65 |

| 28-0-0 | 10.65 |

| 32-0-0 | 11.06 |

| 82-0-0 | 5.15 |

| 12-0-0-26 | 11.50 |

Comparable Concentrations

1 ppm = 1 second in 12 days or 0.013 ounces in 100 gallons or about 8/10 of 1 teaspoon in 1,000 gallons

1 ppb = 1 second in 32 years or 0.013 ounces in 100,000 gallons or about 8/10 of 1 teaspoon in 1,000,000 gal

1 ppt = 1 second in 320 centuries

1 pint of water in ocean = 5,000 molecules in pint of water

1 psi = 2.31 feet

1 foot of lift of water = 0.433 psi

452 gpm = 1inch/1 acre/1 hour

Grain Information

Lb/bu |

Moisture % |

|

| Corn | 56 |

15.5 |

| Soybeans | 60 |

13.0 |

| Grain sorghum | 56 |

14.0 |

| Wheat | 60 |

13.5 |

| Sunflower | 25 |

10.0 |

Cu ft x 0.8 = bushel of grain

Cu ft x 0.4 = bushel of ear corn

| 1 horsepower | = 550 ft lb/second |

| = 33,000 ft lb/minute | |

| = 746 watts |

This publication has been peer reviewed.

Disclaimer Reference to commercial products or trade names is made with the understanding that no discrimination is intended of those not mentioned and no endorsement by University of Nebraska–Lincoln Extension is implied for those mentioned. |

Visit the University of Nebraska–Lincoln Extension Publications Web site for more publications.

Index: Farm Power & Machinery

Machinery

Issued February 2011