G1973

Standard Operating Procedure for E. coli O157:H7 Sampling of Beef Lean Trim

Sampling beef lean trimmings can be used as a verification that the controls for E.coli O157:H7 during slaughter were effective and the lean trimming can be used for ground beef production.

Ben Williams, Graduate Student

Dennis E. Burson, Extension Meat Specialist

- Introduction

- N=60 Sampling Technique

- N=60 Protocol for Collecting E. coli O157:H7 Samples

- Laboratory Methodology

- Summary

Introduction

Beef lean trimmings used to manufacture ground beef provide an opportunity for E. coli O157:H7 contamination. This opportunity occurs by grinding meat that has been exposed to E. coli O157:H7 contamination, usually during the slaughter operation. The ground beef could therefore be contaminated from lean trimmings derived from the outside surface layers of the carcass. Grinding will allow possible contamination to spread throughout the entire batch of ground product and could also contaminate manufacturing equipment, which is commonly used for subsequent batches of product. Because the occurrence of E. coli O157:H7 contamination on surfaces is low, a considerable number of samples need to be evaluated to help ensure product safety.

The sampling protocol involving collection of 60 samples, commonly referred to as N=60 sampling, is an accepted method for meeting product sampling demands in ground beef. This sampling plan is suggested by the International Commission of Microbiological Specifications for Foods and is published in Micro-Organisms in Food, Book 7, Microbiological Testing in Food Safety Management, Kluwer Academic/Plenum Publishers, 2002. The sampling plan selected is Case 15 for a severe hazard and conditions that may increase the concern. Case 15 uses 60 samples and the lot is only accepted if all samples are negative.

N=60 Sampling Technique

The United States Department of Agriculture; Food Safety and Inspection Service (USDA-FSIS) has recommended the N=60 sampling technique for the sampling of E. coli O157:H7 on beef trimmings. The N=60 sampling protocol utilizes an excision method to remove 60 pieces from lean trim surfaces representing the exterior carcass surface. These 60 samples come from a defined lot.

N=60 Protocol for Collecting E. coli O157:H7 Samples

- Assemble all lean trim designated within an identifiable lot. A lot would be all lean trim from a single outside supplier with the same processing date. A lot could be represented by boxes of beef trim or by

2,000 pound combo containers. Small processors may select boxes or trim from one day of production to sample, but large processors should adhere to sample collection standards as described here. Place all trim

samples on hold pending results of the analysis. Do not use the lean trim for grinding or manufacturing until the results are returned.

- Gather the following equipment needed for sampling: caddy, sterile whirl-pack bags from the laboratory, knife, meat hook or tongs, and sterile gloves. Label the whirl-pack bag for the lot and date information.

Sanitize the caddy, knife, hook or tongs before collecting the samples by using a sanitizing solution according to label instructions, or by using hot water (≥180°F) as a sanitizer. Wash and sanitize hands before

sampling. Clean and sanitize hands and equipment between different lots sampled.

- Use sterile gloves to handle all sanitized surfaces so they do not become contaminated.

- Select samples by using the N=60 method of sample collection (described below) and collect 60 individual pieces from raw beef manufacturing trimmings.

- If a specific production lot is composed of greater than five containers (boxes or combos) of beef manufacturing trimmings, randomly select five containers for sampling; and

- If the specific production lot is composed of five or less containers, use the chart below for sampling.

Number of Sample Pieces to Collect Per Container

Number of containers in each production |

Number of pieces to select from each container |

5 |

12 pieces |

4 |

15 pieces |

3 |

20 pieces |

2 |

30 pieces |

1 |

60 pieces |

USDA-FSIS Notice 63-08 |

|

|

- Aseptically collect the appropriate number of beef lean trim pieces based on the number of containers representing one specific production period. Use the sanitized hook or tong to lift a piece of meat off the

top of the container. The total number of pieces collected is to be 60 for each sample.

-

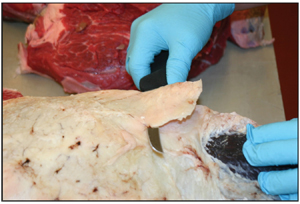

Cut off a slice from each of the 60 pieces approximately 4 inches in length, 1/2 inch in width, and 1/8 inch thick (Beef Industry Food Safety Council Organization, “Best Practices for Using Microbiological

Sampling”). Cut off as much of the trimmings’ outer surface as possible (Figure 1). The priority is to collect samples from pieces of product taken from the original surface of the beef carcass.

- Collect and bag the sample slices in a sterile Whirl-Pak® bag. Confirm that the sample lot and date are indicated on the Whirl-Pak® bag. Weigh the sample to ensure approximately 375 grams of product is

collected. Refrigerate samples prior to shipping.

- Submit the sample to a laboratory. Samples being shipped by overnight delivery must be shipped in insulated containers with ice packs. The selected laboratory must conduct the analysis methods described

below.

- Determine the disposition of the held beef lean trimmings after a certificate of analysis has been received from the laboratory. Lean trimming can be released for grinding when negative test results are received. Lean trimmings with positive test results must not be used for production of ground beef.

Laboratory Methodology

Analysis

- BAX®/PCR should be used (USDA-FSIS Office of Public Health Science MLG 5A.01).

- Include all 375 grams of product to be tested, not a sub-sample.

- Enrichment Method — eight-hour enrichment at 42°C incubation.

- Samples that are BAX®/PCR positive may be further subjected to cultural confirmation.

Result Notification

- Laboratory shall send the test results and the certificate of analysis to the establishment manager by email, fax, or overnight delivery mail. This document will be used for the certificate of analysis.

Summary

Although the N=60 sampling procedure is not 100 percent effective at identifying contamination, it should be sufficient to identify lots of product that are more contaminated than the average. When the expected contamination rate for the sub-samples is ≥ 5 percent, at least one of the 60 sub-samples will test positive 95 percent of the time (statistically) with this sampling process. If positive samples are identified, an evaluation of the production and/or procurement of lean trimmings for manufacturing of ground beef should be conducted. A single positive may be an isolated event, whereas detection of multiple positives, especially in a single day, increases the likelihood of an assignable cause. Although cooking ground beef product to 160°F will destroy the foodborne illness concern, ground beef manufacturers need to apply credible ground beef sampling practices, such as the N=60 sampling protocol, to reduce the possibility for ground beef recalls associated with the pathogen E. coli O157:H7.

This publication has been peer reviewed.

Disclaimer Reference to commercial products or trade names is made with the understanding that no discrimination is intended of those not mentioned and no endorsement by University of Nebraska–Lincoln Extension is implied for those mentioned. |

This publication has been peer reviewed.

Visit the University of Nebraska–Lincoln Extension Publications Web site for more publications.

Index: Foods & Nutrition

Safety

Issued July 2010