Greg R. Kruger, Pesticide Application Technology Specialist

Robert N. Klein, Extension Western Nebraska Crops Specialist

Clyde L. Ogg, Extension Pesticide Educator

Bruno C. Vieira, Post Doctoral Research Associate

Conditions that cause particle drift, and methods that private and commercial applicators can adopt to reduce drift potential from pesticide spray applications, are discussed in this publication.

Spray drift of pesticides away from the target is an important and costly problem facing both commercial and private applicators. Drift problems include:

Drift occurs by two methods: vapor drift and particle drift. This publication focuses on conditions that cause particle drift, and methods to reduce drift potential when spraying pesticides. Potential off-target movement needs to be a primary consideration for all pesticide applications.

A solution sprayed through a nozzle atomizes into droplets that are spherical or nearly spherical in shape. Particle drift is the actual movement of spray particles away from the target area at or near the time of application. Many factors affect this type of drift, but the most important is initial droplet size. Small droplets decelerate quicker than large droplets and fall through the air slowly, making them more likely to be carried farther by air movement.

Droplet size is measured in microns. Droplets with diameters smaller than 100 microns, about the diameter of a human hair, are considered highly driftable. These small droplets cannot be readily seen unless in high concentrations, such as fog. As a result of the small size, drift is more dependent on the irregular movement of turbulent air than on gravity.

Table 1. Effect of droplet size on drift potential (Grisso, et al., 2013).

| Droplet Diameter (microns) | Droplet Size * | Time Requiredto Fall 10 Feet | Lateral Movement in a 3-mph Wind |

|---|---|---|---|

|

20 |

Very fine (VF) |

4.2 minutes |

1,100 feet |

|

100 |

Very fine (VF) |

10 seconds |

44 feet |

|

240 |

Medium (M) |

6 seconds |

28 feet |

|

400 |

Coarse (C) |

2 seconds |

8.5 feet |

|

1,000 |

Extremely coarse (XC) |

1 second |

4.7 feet |

*Droplet size categories in parentheses are based on the American Society of Agricultural and Biological Engineers (ASABE) droplet size classification as described by ASABE S572.1.

Table 1 shows how droplet size affects the rate of fall. The longer the droplet is airborne, the greater the potential for drift.

Figure 1. Lateral movement of water droplets (Hofman and Solseg, 2004).

When exiting the nozzle, a solution may have a velocity of 60 feet per second (41 mph) or more. Unless spray particles are electrostatically charged, there are two forces acting upon the emerging droplets. These forces, gravity and air resistance, greatly influence the deceleration and movement of spray droplets. Air resistance is affected by the direction of the nozzle. There is less air resistance with nozzles aimed away from the direction of travel and wind direction. After their initial speed slows, droplets are more influenced by gravitational pull.

With lower boom heights, the initial speed may be great enough that droplets reach the target before drifting, and prevent off-target movement. Large droplets maintain a downward velocity for a longer time than smaller ones, and are more likely to be deposited on the intended target. Small droplets evaporate quicker than large droplets because of the greater surface area to mass ratio, leaving minute quantities of pesticide in the air (Figure 1). In addition to realizing that spray droplet size is an important factor in reducing drift, an applicator should be aware that nozzles will produce many different sizes of droplets.

Volume median diameter (VMD), a common term used when describing a spray characteristic distribution, is the droplet diameter at which half the spray volume consists of droplets of greater diameter and half consists of droplets of lesser diameter.

The American Society of Agricultural and Biological Engineers (ASABE) developed a droplet size classification system with categories ranging from extremely fine to ultra-coarse, based on the droplet size distribution measured in microns (Table 2). Nozzle catalogs and guides often refer to these droplet size categories, known as spray classification, and color code descriptions to reduce confusion.

An applicator can select the nozzle and pressure based on the spray classification charts. In addition, the pesticide label may list the required or recommended droplet size classification to use with a particular product. For example, the label statement might read: “Apply with 12+ gallons per acre using a nozzle producing a coarse droplet.” The label includes these spray classification recommendations to make sure that the droplet size is suitable for pesticide efficacy. Typically, low-drift nozzles produce spray droplets in the medium (M) to ultra-coarse (UC) range, while reducing the fine droplets—those most likely to drift.

Table 2. Spray classifications with color codes, based on ASABE standards.

Some sprayer components can be adjusted to alter droplet size. Initial selection of the proper nozzle type has the most impact on the resulting droplet size produced (Table 3). For more information on droplet sizes created under various conditions, download Nebraska Extension’s smartphone app “Ground Spray” from the Apple App Store or the Google Play Store.

The following can be altered to modify the applied droplet size.

Different nozzle types produce different spray droplet sizes and patterns.

Spray pressure impacts droplet size with increased pressure reducing overall droplet size. The spray solution emerges from the nozzle in a thin sheet with droplets forming at the edge of the sheet. Higher pressures create a thinner sheet that breaks up into smaller droplets. These smaller droplet sizes created at higher pressure are potentially carried farther downwind than the larger droplet sizes produced at lower pressures (Figure 1). Table 3 shows the mean droplet size for nozzles when spraying at three pressures. Higher pressures decrease droplet size, allowing for more drift potential. Nozzle manufacturers provide specific recommendations for optimum pressure range for different nozzle types.

Large flow rate nozzles with higher carrier volumes produce larger droplet sizes than do smaller orifices. The relationship between flow rate (gallons per minute or GPM) and pressure (pounds per square inch or PSI) is not linear. In order to double the flow rate from a given nozzle, a four times pressure increase is required. This pressure increase consequently reduces droplet size, increasing drift potential and is an undesirable method to increase carrier volume. Rather, it is better to select a larger orifice size that meets the rate requirements at a lower spray pressure. Air inclusion nozzles have two orifices, one to meter the liquid flow and a larger orifice to form the spray pattern. Spray particle sizes depend on the relationship between the orifice sizes and the air inclusion. A lower flow rate nozzle may have a larger particle size when the difference between the two orifice sizes is larger. Consult the pesticide label and EC141, Nozzles—Selection and Sizing, for proper selection.

Table 3. Effect of spray angle and pressure on droplet size (*adapted from Spraying Systems Co., 1990).

| Nozzle spray angle (Degrees) | Volume Median Diameter (VMD), microns | ||

|---|---|---|---|

| 15 PSI | 40 PSI | 60 PSI | |

|

40 |

900 (UC) |

810 (UC) |

780 (UC) |

|

65 |

600 (XC) |

550 (XC) |

530 (XC) |

|

80 |

540 (XC) |

470 (XC) |

450 (XC) |

|

110 |

410 (VC) |

380 (VC) |

360 (VC) |

*Droplet size categories in italics were added based on ASABE droplet size classification now in use.

The spray angle of a nozzle is the distance between the outer edges of the spray pattern, expressed as a number of arc degrees (a full circle is 360°). Wider angles cover a wider spray path and produce a thinner sheet of spray solution and smaller droplets at the same pressure (Table 3). However, wide-angle nozzles can be placed closer to the target, and the benefits of lower nozzle placement may outweigh the disadvantage of slightly smaller droplets. Lower pressures can be used to reduce the amount of fine droplets. For lower pressures with flat-fan nozzles, low pressure or extended range nozzles must be used.

The size or capacity of the nozzle also influences droplet size. A higher flow rate nozzle increases droplet size at a common pressure. Since a higher flow rate nozzle uses more spray volume, it also increases the number of refills; however, the increased volume of carrier solution improves coverage, and in some cases increases pesticide effectiveness. Table 4 shows the influence of increasing flow rate on droplet size at a constant pressure. With some pesticides, such as glyphosate, performance is better at lower carrier volumes.

Table 4. Effect of flow rate on droplet size at 40 PSI (*adapted from Spraying Systems Co., 2007).

| Nozzle type | Volume Median Diameter (VMD), microns | ||

|---|---|---|---|

| 0.3 GPM | 0.4 GPM | 0.5 GPM | |

|

Extended Range Flat-Fan |

270 (C) |

300 (C) |

330 (C) |

|

Drift Guard |

400 (VC) |

425 (XC) |

450 (XC) |

|

Turbo TeeJet |

450 (XC) |

480 (XC) |

510 (XC) |

*Droplet size categories in italics were added based on ASABE droplet size classification now in use.

Operating the boom as close to the sprayed surface as possible, while staying within the manufacturer’s recommendation, reduces drift potential. A wider spray angle allows the boom to be placed closer to the target (Table 5). Booms that bounce cause uneven coverage and drift. Wheel-carried booms stabilize boom height, reduce drift hazard, provide more uniform coverage, and permit lower boom height. Boom height controllers are now optional on most sprayers. The nozzle height suggestions in Table 5 are based on the minimum overlap required for uniform spray distribution. In many cases, however, height adjustments are based on a 1-to-1 nozzle spacing-to-height ratio. For example, 110° flat spray tips with 20-inch spacing usually are set 20 inches above the target.

Nozzle spacing is the distance between individual nozzles on the spray boom and is critical to achieving adequate spray coverage. Spray angle and boom height also are key in the resulting coverage achieved. At a given spray volume, as the spacing between nozzles increases, nozzle flow rate must also be increased to maintain the volume applied. This typically means increasing the boom height to get the proper overlap. However, increasing droplet size is more important than reducing boom height.

It is important to follow the equipment and nozzle manufacturer’s recommendations for appropriate nozzle configuration. As a general guideline, do not exceed a 30-inch nozzle spacing as the spray pattern will be less uniform. A configuration of nozzle spacing, height, and direction that gives proper spray overlap is preferred for broadcast applications. The best nozzle spacing for most sprayers is 15 inches. Specifically for high volumes, use a 15-inch nozzle spacing and for low volumes, cap off every other nozzle and use a 30-inch nozzle spacing.

Both the amount of pesticide lost from the target area, and the distance it moves downwind, increase as wind speed increases (Table 6). Severe drift injury can occur with low wind velocities as well, especially under temperature inversions. Inversions can also lead to pesticide movement in any direction following subsequent winds when the inversion starts to lift. Most recommendations are to stop spraying if wind speeds are less than 3 mph or exceed 10 mph. Some product labels have application restrictions when winds are higher than 8 mph, some have 15 mph cut-offs, and others do not specify. Therefore it is important to consult the product label for exact restrictions of the product being applied. The wind effect can be minimized by using larger droplet sizes, shielded booms, and lower boom heights.

Pesticides should not be applied when the wind is blowing toward a nearby susceptible crop, a crop in a vulnerable stage of growth, or sensitive areas such as beehives. Select a time when there is little wind or the wind blows gently away from sensitive areas. If these conditions do not exist, consider another method of control or time of application.

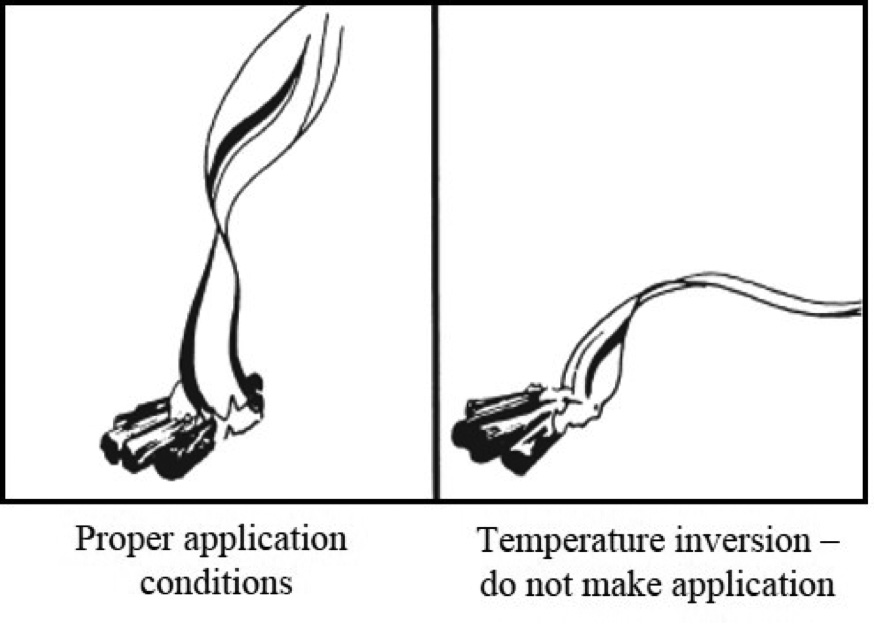

Air movement largely determines the distribution of spray droplets. Often wind is recognized as the most important factor, but vertical air movement is often overlooked. Temperature inversions occur when cool air near the soil surface is trapped under a layer of warmer air. A strong inversion potential occurs when ground air is 2–5°F cooler than the air above it and there is no wind.

Under inversion conditions spray drift can be severe. Small spray droplets may fall slowly or be suspended and move several miles to susceptible areas, carried by a gentle breeze. Do not apply pesticides near susceptible crops or other sensitive areas during temperature inversion conditions. Inversions can be identified by observing smoke from a smoke bomb or a fire (Figure 2). Smoke moving horizontally close to the ground is indicative of a temperature inversion.

Table 5. Suggested minimum spray height above spray contact surface. (Most nozzle manufacturers have nozzles similar to the TeeJet nozzles listed below).

| Nozzle | Spray angle degrees | Spray height, inches | ||

|---|---|---|---|---|

| 20-inch nozzle spacing | 30-inch nozzle spacing | 40-inch nozzle spacing | ||

|

TP, TJ |

65° |

22–24” |

30–35” |

NR* |

|

TP, XR, TX, DG, TJ, AI, XRC |

80° |

17–19” |

26–28” |

NR* |

|

TP, XR, DG, TT, TTI, TJ, DGTJ, AI, AIXR, AIC, XRC, TTJ, AITTJ |

110° |

16–18” |

20–22” |

NR* |

|

FullJet® |

120° |

10–18”** |

14–18”** |

14–18”** |

|

FloodJet®TK, TF, K, QCK, QCTF, 1/4TTJ |

120° |

14–16”*** |

15–17”*** |

18–20”*** |

*Not recommended.

**Nozzle height based on 30° to 45° angle of orientation.

***Wide angle spray tip height is influenced by nozzle direction. The critical factor is to achieve a double spray pattern overlap.

Source: TeeJet Technologies Catalog 51A.

Table 6. Effect of wind speed on drift in a 10-foot fall (*adapted from Ross and Lembi, 1985)

| Droplet diameter (microns) | Drift (feet) | |

|---|---|---|

| 1 mph winds | 5 mph winds | |

|

100 (VF) |

15 |

77 |

|

400 (VC) |

3 |

15 |

*Droplet size categories in italics were added based on ASABE droplet size classification now in use.

Figure 2. Smoke movement indicates temperature inversion conditions.

Low relative humidity and/or high temperature conditions cause faster evaporation of spray droplets and a higher potential for drift. During evaporation, the spray solution generally loses more water than pesticide, creating smaller droplets with a greater concentration of pesticide. The quantity of spray that evaporates from the target surface is related to the quantity of spray deposited on that surface. Smaller droplets, being more prone to drift and evaporation, have less chance of actually being deposited on the target surface than do large droplets. Therefore, hot and dry weather conditions lead to less spray deposition and more drift, due to evaporation of the spray carrier solution.

Evaporation increases the potential for drift, so it is recommended to spray during lower temperature and higher humidity conditions. Pesticides differ in their evaporation rate. Use formulations and adjuvants that reduce evaporation when possible. Some pesticide labels specify relative humidity and temperature conditions for product use. Generally, if the relative humidity is above 70%, conditions are ideal for spraying. A relative humidity below 50% percent is low enough to warrant additional caution.

Some spray adjuvants and formulations act as spray thickeners or drift retardants when added to a spray tank. These materials increase the number of larger droplets and decrease the number of fine droplets. They tend to give water-based sprays a “stringy” quality and reduce drift potential.

All nozzles produce a range of droplet sizes. The small, drift-prone particles cannot be eliminated but can be reduced and kept within reasonable limits. Here are some tips:

Elliot, J.G. and B.J. Wilson, editors. 1983. The influence of weather on the efficiency and safety of pesticide application. The drift of herbicides. Occasional Publ. No. 3. BCPC Publs., Croydon, England.

Grisso, R., P. Hipkins, S. Askew, L. Hipkins, and D. McCall. 2013. Nozzles: Selection and Sizing. Virginia Cooperative Extension, Publication 442–032.

Hansen, G., F.E. Oliver, and N.E. Otto. 1983. Herbicide manual, a water resources technical publication. U.S. Government Printing Office, Denver, Colo.

Hartley, G.S. and I.J. Graham-Bryce. 1980. Physical principles of pesticide behavior. Vol. 1 Academic Press Inc., New York, N.Y.

Haskel, P.T., editor. 1985. Pesticide application: principles and practice. Oxford University Press, New York, N.Y.

Hofman, V. and E. Solseg. 2004. Spray equipment and calibration. North Dakota State University Extension AE-73. North Dakota State University, Fargo, ND.

Matthews, G.A. 1979. Pesticide Application Methods. Longman, Inc., New York, N.Y.

Pearson, S. 1989. Don’t get my drift. In: Grounds Maintenance 25(1): 32, 36, 38.

Ross, Merrill A. and Carole A. Lembi. 1985. Applied Weed Science. Burgess Publishing Company, Minneapolis, Minn.

Spraying Systems Company. 1990. TeeJet Catalog 42, Agricultural Spray Products. Wheaton, Ill.

Spraying Systems Company. 2007. TeeJet Catalog 50, Agricultural Spray Products. Wheaton, Ill.

Reference to commercial products or trade names is made with the understanding that no discrimination is intended of those not mentioned and no endorsement by Nebraska Extension is implied for those mentioned.

This publication has been peer reviewed.

Nebraska Extension publications are available online at http://extensionpubs.unl.edu/.

Extension is a Division of the Institute of Agriculture and Natural Resources at the University of Nebraska–Lincoln cooperating with the Counties and the United States Department of Agriculture.

Nebraska Extension educational programs abide with the nondiscrimination policies of the University of Nebraska–Lincoln and the United States Department of Agriculture.

© 2019, The Board of Regents of the University of Nebraska on behalf of the Nebraska Extension. All rights reserved.