G2233

Home Efficiency: Insulation

Properly installed insulation can help keep heat in during winter months. This publications explains options for insulation and provides tips for other energy-saving measures.

F. John Hay, Extension Educator – Energy

Lynn Chamberlin, Nebraska Energy Office

Keeping warm in poorly insulated homes costs so much because the heat doesn’t stay in the home very long. Warm air produced by your heating system naturally wants to go to cold areas or surfaces. As a result, heat travels right through your home’s walls, floors, and roof. This is called heat loss, and to compensate for the heat loss, the furnace will need to operate more, costing you money.

Insulation materials placed in walls, floors, and the under the roof slows heat loss. During the winter, insulation keeps the heat in, and during the summer, insulation works to keep your house cooler by keeping the heat out. If you can afford it, increasing insulation R-values beyond recommended levels is a wise choice.

Resistance is Key

The ability of insulation material to reduce heat flow is measured in terms of “resistance” or “R-value.” It is most often measured per inch of material. The higher the R-value, the better the insulation properties of the material used. In Nebraska, it is recommended that the attic of an existing home be insulated between a R-38 and a R-49, floors to R-30, and exterior walls to R-13. Achieving these R-values depends on the type and thickness of insulation installed. For example, fiberglass batt insulation has an R-value of around 3.4 per inch of insulation, so one 3½-inch batt will insulate a wall cavity to about R-12. The R-value of extruded polystyrene board insulation is R-5 per inch, so just 2 inches of that material has close to the same insulation effectiveness as the fiberglass.

Insulation Types

Different types of insulation have different uses. It’s important to select the right type of insulation for the job you’re doing and to install it according to manufacturer’s instructions so it will be as effective as possible.

The easiest time to install insulation is when your home is under construction, but it also can be added to most existing houses.

Insulation can be purchased in four basic forms:

- Batts or blankets

- Loose-fill

- Rigid board

- Foamed-in-place

Batts or Blankets. Insulation batts or blankets consist of fibers made from spun rock, slag, or glass. Glass fiber, the most common insulation, is made from glass and has an R-value of 2.2 to 3.2 per inch. Rock or mineral wool, made from rock or slag, has an R-value of 3.1 per inch.

Batts are cut to specific lengths, and blankets come in long “cut-it-yourself” rolls. Both types are available in thicknesses that range from 1-12 inches and are wide enough to fit into a standard 16-inch or 24-inch wall cavity opening, depending on your insulation needs. Batts and blankets work well when the space you want to insulate is an unfinished, framed-in area. Common applications include insulating unfinished walls, open attics, and basement or crawl space ceilings. You can buy batt and roll insulation with a built-in vapor retarders made of kraft paper, or you can buy it “unfaced” (without a vapor retarder) and install one separately if needed. A vapor retarder helps prevent moisture infiltration and absorption. Moisture absorbed into insulation lessens its effectiveness. Both glass-fiber and mineral wool are non-flammable, but their vapor retarders aren’t, so they must be covered with a fireproof material such as sheetrock. It is also important not to compress batt or blanket insulation into a tight space. The insulation relies on tiny air pockets to slow heat flow, and crushing these pockets decreases the insulation’s effectiveness.

Loose Fill. This type of insulation comes in bags and can be made from cellulose (shredded newsprint or wood fibers), glass-fiber and mineral wool. The R-values range from 2.2 per inch for glass-fiber to 3.7 per inch for cellulose fiber. For maximum R-value effectiveness, it’s important to install loose fill insulations to the proper density. Cellulose, glass-fiber and mineral wool loose-fill insulations are most commonly installed by a professional who blows it into finished walls and open or finished attic spaces. By applying special adhesives to loose-fill insulation, unfinished wall spaces can also be insulated. The adhesives assure that the insulation will not settle in the space.

Rigid Board. Rigid board insulations are made from a wide range of plastic materials, including expanded polystyrene (R 4.0 to 4.5 per inch), extruded polystyrene (R 5.0 to 5.5 per inch), polyurethane (R 6 to 7.5 per inch), and polyisocyanurate (R 6 to 7.5 per inch). Because of its ability to resist moisture damage, polystyrene rigid board insulations are commonly used in basement and crawl space walls and around slab foundations. Any rigid board products can be used to insulate cathedral ceilings and insulation sheathing under exterior siding. Many rigid board insulations are flammable and must be covered with a fire-resistant material such as sheetrock.

Foamed-in-Place. Insulation is also available in a foam form that can be sprayed into walls or roof cavities. Foam insulations are often denoted as open-cell or closed-cell which refers to their density. Differing densities generally impact the R-value per inch and the vapor transmitting qualities of the insulation. The most common is a polyurethane product that when foamed-in-place has an R-value of about 6 per inch.

Advantages of foamed-in-place insulations include excellent air sealing and vapor control, and excellent insulation qualities.

General Guidelines

- Seal first, then insulate. Adding insulation to your home’s attic, walls, or floors will not be effective if heat can easily travel through cracks and holes between framing members and around windows and doors. Seal all major cracks and openings before insulating.

- Ensure adequate ventilation. Adding insulation increases the need for ventilation, especially in attics and crawl spaces. Pay close attention to ventilation and or vapor barrier requirements for these areas.

Where to Insulate

Because warm air naturally rises, the attic or roof area of your home should be a first priority for insulating. Insulation reduces the upward flow of heat, keeping it inside your home longer. That means you’ll stay warmer, your heating system will not come on as often, and you can reduce your utility costs.

In Nebraska’s cold climate, insulating existing attics to an R-value of between 38 and 49 is recommended. Both glass fiber and loose-fill cellulose are commonly used to insulate attics. Twelve inches of the glass fiber batt insulation achieves R-38, and about 10½ inches of cellulose will do the trick. How much insulation is in your attic?

Attic/Roof Types

How your attic should be insulated depends on how your roof is built. Common attic/roof types are:

- Unfinished Attic. In these homes, the attic is not part of the living space. You can often get into the attic by ladder through a hatch usually located in a hallway or closet ceiling. Unfinished attics are generally the easiest type to insulate; the insulation goes between the framing members (joists) of the attic floor, which is also your living area’s ceiling. Capable do-it-yourselfers can tackle this job with advice from a professional. Rolls of glass fiber or loose-fill cellulose have been the insulation of choice for most do-it-yourself jobs. This publication primarily deals with steps you can take to add insulation to your unfinished attic.

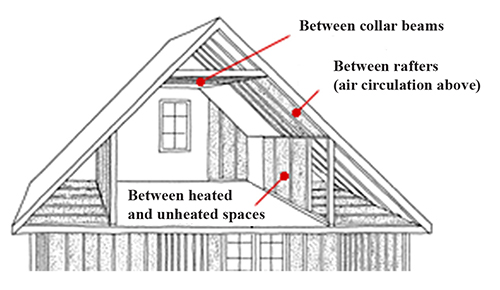

- Finished Attic. A portion of these attics are living spaces. As a result, insulation should be placed in the exterior walls (called kneewalls), the entire ceiling and the outer floor areas that are not part of the living space. This type of attic insulation project often requires the use of several insulation products.

|

- Flat, Vaulted, or Cathedral Ceilings. These types of ceilings don’t have attics above them, and due to little or no space to add insulation, it may be impossible to add insulation to this roof type. If there is space, the insulation must be blown or placed between the interior ceiling and the exterior roof. However, it is very important that these construction types be well-ventilated and sealed to prevent moisture problems. This type of work often requires the expertise of a contractor.

Adding Insulation to Unfinished Attic

Here are the steps either you or a weatherization contractor should take to insulate or add insulation to an unfinished attic:

- Be an attic detective. Go into the attic with a flashlight and a dust mask to investigate. CAUTION: If you find vermiculite insulation in your attic, DO NOT PROCEED. Vermiculite was mined in the U.S. before 1990 and much of it came from a mine that was contaminated with asbestos. Since vermiculite may contain asbestos, always have it tested before continuing.

Construct a makeshift walkway by laying boards on top of the joists, because the ceiling below won’t support your weight. Measure the amount of insulation present and determine its type. It is most likely mineral or rock wool, glass fiber, or cellulose fiber. You can take a sample to your local building materials supplier if you are unsure. If there is already insulation up there and it’s dry and evenly spread out, you can leave it alone and, if needed, add more insulation on top. You can put batt insulation over existing loose-fill or vice versa. Just make sure that the new insulation doesn’t have a vapor retarder which would trap moisture inside the old insulation. If the existing insulation is or has been wet, find and correct the moisture problem before doing any insulating. It could be caused by a leaky roof or too much air leaking up from your living space. When warm air from your house rises into the attic, it also carries with it large amounts of moisture. When the moisture hits the cold surfaces of your attic, it can condense and cause a number of problems — wet insulation that doesn’t insulate well, mold growth, and damage to sheetrock and other building materials. To help control moisture, make sure bathroom and kitchen vents are not vented directly into the attic. They should be vented to the outside, through the roof.

-

Electrical. Check all wiring and electrical junction boxes to assure wiring is not exposed and boxes are appropriately covered. Many old homes have a two-wire system referred to as “knob and tube wiring” (Figure 1). This type of wiring should not be covered with insulation.

Figure 1. Knob and tube wiring

- Seal air leaks. Insulating won’t save you much money or keep you much warmer unless you first seal all the air (and moisture) passageways between your living space and your attic. Common air leakage spots include the tops of interior and exterior walls, around pipes and heating ducts, light fixtures, and wires. Conventional caulking methods work fine, though special care should be taken around chimneys and plumbing stacks that may require special types of caulk (ask your local material supplier). You also should weatherstrip, seal, and secure the attic hatch door, treating it as you would a door to the outside.

- Ensure enough ventilation. Proper ventilation is another key to a successful attic insulation job. It lets your attic breathe, ridding it of moisture in the winter, and keeping it cooler in summer. If your attic has a vapor retarder, you need 1 square foot of free vent area for every 300 square feet of attic floor area. Without a vapor retarder, you need twice as much ventilation — 1 square foot of vent for every 150 square feet of floor. Vents should be located on opposite ends of the attic, with some near the top and others near the bottom to allow for good cross-ventilation. Talk with a contractor about which types of vents would be best for your attic.

- Remove possible moisture sources. Bathroom fans that are vented into the attic area carry large amounts of warm, hot air into a very cold space during Nebraska winters. This excess moisture can condense on any number of surfaces in the attic and contribute to mold growth, insulation damage, and roof rot. Make sure all exhaust fans are vented to the outside of the attic.

-

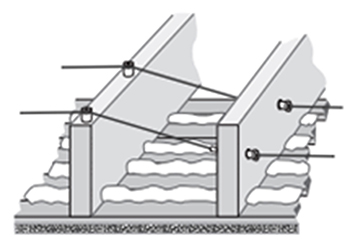

Insulation. Now you’re ready to either roll out the batts or install the loose-fill. You may want to use some of both, putting batts in the straight-a-ways and loose-fill in the nooks and crannies. Buy batts wide enough to snugly fit between the attic framing members. First fill the joist spaces, and then roll out a second layer on top, perpendicular to the first (Figure 2). Be sure to place the batts as close together as possible. If you opt for loose-fill insulation, make sure to install it level. If you plan to add loose-fill above the height of the joists, attach marked wooden sticks to the joists to serve as depth markers.

Figure 2. Batt insulation added to an unfinished attic

As you add insulation, it’s important to not block any combustion air supply source or any ventilation openings, especially in the eaves. Ventilation chutes can be created during the insulation job to prevent vents from being blocked off. Also, keep insulation at least 3 inches away from recessed light fixtures, chimneys, fan motors, and flues to reduce fire danger. Do this by surrounding the objects with a sheet metal barrier that extends at least 4 inches above the finished insulation level. If you have a water heater, furnace, or knob and tube wiring in your attic, consult a professional for information on insulating around these obstacles. Whatever insulation type you choose, follow the manufacturer’s directions carefully and don’t unwrap the insulation until you get it up in the attic. Also, since you’ll be spending time in a dusty space, wear a respirator dust mask, work gloves, and protective clothing. It’s a dirty job, but well worth doing!

This publication has been peer reviewed.

Visit the University of Nebraska–Lincoln Extension Publications website for more publications.

Index: Consumer Education

Energy Conservation

Issued April 2014