G1999

How to Formulate Lactating Dairy Rations to Include Corn Milling Co-Products

Corn milling co-products have a high nutritional value for dairy cows. Following the guidelines here will allow you to formulate more accurate, precise, and cheaper rations.

Kimberly J. Clark, Research Coordinator

Paul J. Kononoff, Extension Dairy Nutrition Specialist

- Introduction

- Formulating Rations for Lactating Dairy Cows

- Chemical Composition of DDGS and WDGS

- Nutrient Guidelines for Lactating Dairy Rations

- Total Mixed Ration Particle Size

- Diet Examples that Include Co-Products

- Nutrient Comparison of Rations

- Corn Milling Co-product Cost

- Summary

Introduction

The ethanol industry plays a large role in United States agriculture. In 2008, Nebraska produced nearly 1.6 billion gallons of ethanol in 23 plants, thus making corn milling co-products highly available to the Nebraska dairy industry.

Corn milling co-products have a high nutritional value (protein, energy, and minerals) for dairy cows, which aid in maintaining milk production and animal health. However, the chemical composition of co-products may vary among and within production plants, creating challenges when formulating rations. Typically, distillers grains in rations are included in limited quantities due to the limited research with co-products in lactating dairy rations; however, recent studies at the University of Nebraska–Lincoln have shown that dried distillers grains plus solubles (DDGS) may be included up to 30 percent of the ration dry matter and maintain normal milk production.

Several computer software programs are commonly used when formulating dairy rations. One example is Cornell-Penn-Miner Dairy (CPM-Dairy, Version 3.0.10). Based on inputs describing the animal, level of milk production, and the diet, this program is capable of estimating dry matter intake, metabolizable protein and metabolizable energy, and nutrient composition of the diet. Before balancing rations using CPM-Dairy, the chemical composition of all feedstuffs in the ration should be well characterized to improve the precision. Using CPM-Dairy should result in a properly balanced ration that supports milk production and animal health.

The objectives of this NebGuide are to:

- discuss formulating lactating dairy cow rations,

- describe the chemical composition of DDGS and wet distillers grains plus solubles (WDGS) for use in the lactating dairy cow diet,

- describe the nutrient guidelines of lactating dairy rations,

- evaluate particle size of the ration when corn milling co-products are included in lactating dairy diets,

- formulate and compare a control diet, 15 percent DDGS inclusion level diet, and a 30 percent inclusion level of DDGS for lactating dairy cattle, and

- compare rations costs of diets with and without corn milling co-products.

Formulating Rations for Lactating Dairy Cows

Accurately understanding key herd performance measures, such as dry matter intake, milk production, body weight, and body condition score, makes the ration formulation process easier and more precise. Additionally, several feed ingredients such as corn grain, soybean meal, bypass soy supplements, and forages such as corn silage and alfalfa hay are reduced or substituted in order to properly balance the lactating dairy ration. When substituting or reducing these feedstuffs, it is important to carefully consider the chemical composition (crude protein, starch, fat, neutral detergent fiber, for example) of each feedstuff.

Chemical Composition of DDGS and WDGS

The process of producing ethanol is variable, which causes the chemical composition of co-products to vary. Based on data available from Dairy One Forage Laboratory (Ithaca, N.Y.), Table I lists the nutrient composition of DDGS and WDGS. Both DDGS and WDGS are low in starch (5.6 ± 4.8% and 5.9 ± 10.4%, respectively) and high in crude protein (30.7 ± 4.0% and 29.8 ± 10.9%), neutral detergent fiber (33.5 ± 4.5% and 29.9 ± 9.6%), and fat (13.1 ± 3.0% and 12.6 ± 4.4%). It is important to periodically sample and analyze the co-product to determine an accurate chemical composition.

| Table I. Nutrient composition of dried distillers grains plus solubles (DDGS) and wet distillers grains plus solubles (WDGS) from Dairy One Forage Laboratory (Ithaca, N.Y.). | ||||||

| Nutrient | DDGS |

WDGS |

||||

n1 |

Mean |

SD2 |

n1 |

Mean |

SD2 |

|

| Dry matter, % | 3971 |

88.0 |

7.7 |

1532 |

31.4 |

13.6 |

| Crude protein, % | 3774 |

30.7 |

4.0 |

1526 |

29.8 |

10.9 |

| Acid detergent insoluble nitrogen, % of N | 3282 |

4.7 |

2.0 |

1436 |

3.5 |

2.1 |

| Neutral detergent insoluble crude protein, % | 1372 |

9.5 |

3.0 |

974 |

8.0 |

3.9 |

| Lignin, % | 1470 |

5.1 |

1.7 |

596 |

4.7 |

1.7 |

| Acid detergent fiber, % | 3278 |

16.8 |

3.5 |

1406 |

14.7 |

5.4 |

| Neutral detergent fiber, % | 3264 |

33.5 |

4.5 |

1417 |

29.9 |

9.6 |

| Starch, % | 2048 |

5.6 |

4.8 |

820 |

5.9 |

10.4 |

| Fat, % | 2865 |

13.1 |

3.0 |

1011 |

12.6 |

4.4 |

| Ash, % | 1646 |

5.9 |

1.1 |

581 |

5.5 |

1.8 |

| Total digestible nutrients, % | 3256 |

83.5 |

4.5 |

1417 |

85.2 |

5.2 |

| IVTD3 24h, % | 44 |

84.6 |

2.3 |

5 |

81.1 |

0.0 |

| NDFD4 24h, % of NDF | 44 |

54.0 |

7.0 |

5 |

51.8 |

0.0 |

| IVTD3 48h, % | 26 |

89.2 |

3.0 |

5 |

82.7 |

0.0 |

| NDFD4 48h, % of NDF | 26 |

67.9 |

10.5 |

5 |

65.3 |

0.0 |

| Ca, % | 2756 |

0.1 |

0.1 |

801 |

0.1 |

0.1 |

| P, % | 2775 |

0.9 |

0.2 |

802 |

0.9 |

0.2 |

| Mg, % | 2742 |

0.3 |

0.1 |

800 |

0.3 |

0.1 |

| K, % | 2743 |

1.1 |

0.2 |

799 |

1.0 |

0.3 |

| Na, % | 2165 |

0.2 |

0.2 |

690 |

0.2 |

0.1 |

| S, % | 2088 |

0.7 |

0.2 |

677 |

0.6 |

0.2 |

| Cl, % | 461 |

0.2 |

0.1 |

176 |

0.2 |

0.1 |

| Ammonia, % | 65 |

0.5 |

1.1 |

578 |

4.8 |

9.2 |

| pH | 678 |

3.9 |

0.2 |

399 |

3.9 |

0.2 |

| 1n = number of samples 2SD = standard deviation 3IVTD = in vitro total digestibility 4NDFD = neutral detergent fiber digestibility |

||||||

Nutrient Guidelines for Lactating Dairy Rations

There are nutrient guidelines to follow when formulating rations. Nutrient considerations of the ration include neutral detergent fiber, starch, crude protein, metabolizable protein and metabolizable energy, lysine to methionine ratio, and fat. Neutral detergent fiber should be at least 26 percent of the ration DM to maintain a healthy rumen. The National Research Council: Nutrient Requirements for Dairy Cattle (2001) recommends neutral detergent fiber from forage to be at least 19 percent of the ration dry matter. However, in most cases, rations are usually 22-28 percent neutral detergent fiber of the ration dry matter.

Starch, a nonstructural carbohydrate, is highly digestible and important to meet the energy demands of lactating dairy cattle. Diets which contain adequate amounts of energy may contain less than 23 percent starch when corn grain is replaced with corn milling co-products; however, ruminants have a requirement for energy, not starch per se.

It is recommended by CPM-Dairy that, on average, lactating dairy diets contain about 18 percent crude protein. It is important to note that dairy cows do not have a requirement for crude protein but rather metabolizable protein. Crude protein in the diet aids in meeting metabolizable protein requirements. Metabolizable energy and metabolizable protein are the energy and protein available in the ration to support lactation. The amount of metabolizable energy and protein in the ration should be slightly higher than the group milk yield average to avoid a decrease in milk production from higher producing dairy cattle. Rumen degradable and undegradable protein are two types of protein included in the diet. Rumen degradable protein is the protein fraction degraded in the rumen and utilized by microbes. Additionally, rumen undegradable protein is not degraded in the rumen and available for digestion in the small intestine. As co-products such as DDGS increase in the diet, rumen undegradable protein increases, also.

Legumes such as alfalfa hay are high in lysine, while corn products are high in methionine. In diets containing high levels of legumes and soy-based protein, methionine is typically the most common limiting amino acid. However, as corn silage, corn grain, and co-products are included in the lactating dairy ration, lysine is believed to become more limiting due to a decrease of forages in the diet. In diets formulated to contain low levels of crude protein (less than 16 percent), a 3.0:1.0 ratio of lysine to methionine in duodenal flow is recommended to balance limiting amino acids. In order to reach this level, bypass soy or fishmeal products may need to be included in the ration. It is important to note, meeting the recommended lysine:methionine ratio is less important when rations contain higher levels of crude protein, which is often the case when rations contain co-products.

Attempts should be made to keep fat levels at 5 percent or less, although this is not always possible. Rations with greater amounts of fat may decrease dry matter intake due to the decreased palatability of the ration. Additionally, fat may decrease rumen fermentation and fiber digestibility. Dried distillers grains plus solubles and WDGS tend to have a higher fat level compared to the feedstuffs they are replacing or substituting; therefore, increasing the inclusion level of co-products in the diet may increase the level of fat to more than 5 percent.

Total Mixed Ration Particle Size

When including co-products in lactating dairy diets, the particle size of the ration must be adequate to maintain animal health. Fiber containing feeds with a course particle size, such as hay, are higher in effective fiber. Effective fiber is long roughage fiber particles, which stimulate rumination, chewing activity, and salivation. As rumen pH levels become acidic, fiber digestion may become slowed and milk fat levels may decrease; therefore, effective fiber aids in maintaining healthy rumen functions and pH levels. Large particles (>0.75 inches) should account for 2-8 percent of the total mixed ration using the Penn State Particle Separator.

Dried distillers grains plus solubles and WDGS have a finer particle size compared to the feedstuffs being substituted or reduced. Therefore, as co-products are added to rations, the particle size of the ration often becomes finer, which may reduce normal ruminating activity. To prevent this, it may be useful to include some coarser, higher fiber forages such as wheat straw or brome hay.

Diet Examples that Include Co-Products

To demonstrate how rations may be balanced to contain higher levels of DDGS, the nutrient composition of a sample co-product, listed in Table II, was entered into the CPM-Dairy Model. Three rations were formulated using CPM-Dairy and are described in Table III. The first ration is a typical lactating dairy ration which does not contain DDGS, while the other two rations contain 15 percent and 30 percent DDGS on a DM basis. Each ration assumes a body weight of 1,330 pounds, body condition score 3.0, third lactation, 120 days in milk, 0.24 lb/day growth, and a moderate milk production level (75.0 lb/day).

To make room for DDGS, corn silage and ground corn were reduced due to their high energy compared to DDGS. Additionally, SBM and soybean hulls were reduced due to their higher protein and energy values compared to DDGS. Alfalfa hay and haylage were reduced in the diet as co-products were added due to the protein levels in alfalfa hay and haylage; however, brome hay increased in the diet for added effective fiber to maintain normal rumen activity. Bypass soy, cottonseed lint, and fat were substituted or reduced as DDGS were included in the diet due to their high fat or rumen undegradable protein content. When substituting or reducing feedstuffs in the ration, the chemical composition of each feedstuff should be known.

| Table II. Nutrient composition of dried distillers grains plus solubles (n = 30). | ||

| Nutrient | Mean |

SD1 |

| Crude protein, % | 30.8 |

0.6 |

| Acid detergent fiber, % | 12.8 |

1.6 |

| Neutral detergent fiber, % | 32.9 |

1.6 |

| Neutral detergent fiber with NaSO3, % | 30.0 |

3.3 |

| Acid detergent insoluble nitrogen, % of crude protein | 3.0 |

1.1 |

| Fat, % | 11.2 |

0.5 |

| Lignin, % | 4.1 |

1.2 |

| DMD2-24h in vitro, % | 54.2 |

3.1 |

| DMD2-48h in vitro, % | 68.8 |

4.3 |

| NDFD3-24h in vitro, % of NDF | 75.6 |

3.6 |

NDFD3-48h in vitro, % of NDF |

86.3 |

2.7 |

| 1SD = standard deviation 2DMD = dry matter digestibility for 24 hours or 48 hours 3NDFD = neutral detergent fiber digestibility for 24 hours or 48 hours |

||

| Table III. Lactating dairy ration diet feeding a control, 15 percent DDGS and 30 percent DDGS and cost per ration per cow. | ||||

| Ingredient | Cost-

$/lb DM |

Diet-lb/d DM |

||

Control |

15%

DDGS |

30%

DDGS |

||

| DDGS | 0.09 |

— |

6.9 |

14.0 |

| Corn silage | 0.04 |

12.0 |

12.0 |

9.2 |

| Ground corn | 0.11 |

9.3 |

6.4 |

5.6 |

| Soybean meal | 0.15 |

4.02 |

2.85 |

1.7 |

| Soybean hulls | 0.09 |

4.7 |

3.4 |

2.1 |

| Brome hay | 0.07 |

3.0 |

7.0 |

7.0 |

| Alfalfa haylage | 0.09 |

4.64 |

2.5 |

1.7 |

| Alfalfa hay | 0.09 |

2.5 |

2.5 |

1.7 |

| By-pass soy | 0.24 |

2.0 |

1.3 |

0.75 |

| Cottonseed lint | 0.15 |

1.5 |

— |

— |

| Fat | 0.33 |

0.2 |

— |

— |

| Vitamins and minerals | 0.51 |

1.14 |

1.24 |

1.27 |

| Total Intake-lb/day DM | 45.0 |

46.1 |

45.0 |

|

| Ration Cost-$/cow/day | 4.73 |

4.42 |

4.31 |

|

Nutrient Comparison of Rations

Table IV lists the nutrient composition of the three rations that were formulated to increase the level of DDGS in the ration. The crude protein content increases as co-products increase in the diet (17.9, 17.8, and 19.0 for control, 15 percent DDGS, and 30 percent DDGS, respectively). In comparison, the percent of starch in the diet decreases with increasing levels of DDGS (26.1, 21.9, and 19.7 for control, 15 percent DDGS, and 30 percent DDGS, respectively). Although starch level is less than the recommended 23 percent of the ration dry matter, metabolizable energy is sufficient to meet the energy needs of the animal. Neutral detergent fiber increases as DDGS are added to the ration (34.4, 36.9, and 35.9 percent for control, 15 percent DDGS, and 30 percent DDGS, respectively). Fermentable starch and fermentable neutral detergent fiber are components of carbohydrates which are digested by the animal. Fermentable starch decreases as starch levels in the diet decrease (21.8, 18.3, and 16.5 percent for control, 15 percent DDGS, and 30 percent DDGS, respectively) while fermentable neutral detergent fiber increases with the inclusion of DDGS (12.5, 13.8, and 13.4 percent for control, 15 percent DDGS, and 30 percent DDGS, respectively). Because DDGS are higher in fat than the feedstuffs being replaced, the fat content in the ration increases as DDGS increase (3.9, 4.5, and 6.2 percent for control, 15 percent DDGS, and 30 percent DDGS, respectively). Despite these changes, both metabolizable protein and energy remain at 75.0 lb/day or greater, adequate to meet the protein and energy needs of the animal.

| Table IV. Nutrient composition of control, 15 percent DDGS and 30 percent DDGS diets assuming there is 75.0 lb of milk produced daily. | |||

| Nutrient | Diet |

||

Control |

15% DDGS |

30% DDGS |

|

| Dry matter intake, lb/d DM | 45.0 |

46.1 |

45.0 |

| Crude protein, % DM | 17.9 |

17.8 |

19.0 |

| Starch, % DM | 26.1 |

21.9 |

19.7 |

| Fat, % DM | 3.9 |

4.5 |

6.2 |

| Neutral detergent fiber, % DM | 34.4 |

36.9 |

35.9 |

| Lysine:Methionine | 3.5:1 |

3.0:1 |

2.6:1 |

| Metabolizable energy, lb/d | 75.6 |

75.2 |

75.6 |

| Metabolizable protein, lb/d | 75.4 |

75.0 |

76.1 |

| Fermentable NDF, % DMI | 12.5 |

13.8 |

13.4 |

| Fermentable Starch, % DMI | 21.8 |

18.3 |

16.5 |

Corn Milling Co-product Cost

Ethanol production is year round which provides corn milling co-products that are readily available for dairy producers. The price of corn milling co-products is based on the current corn market price; however, the corn market tends to be variable. Consequently, the pricing of co-products is not always straightforward.

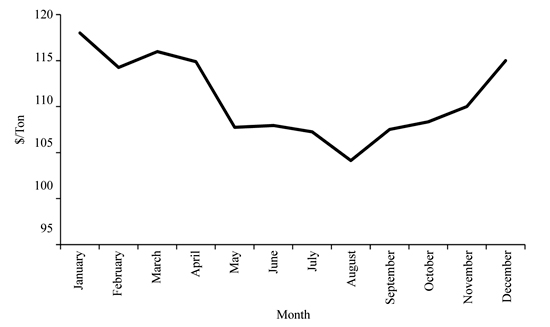

Dried distillers grains plus solubles and WDGS can be compared in prices. Because DDGS are further dried, additional processing occurs which increases the price of DDGS compared to WDGS. Although co-products may be used in dairy rations year round, the demand for co-products decreases in the summer months, due to fewer cattle being in feedlots in the United States, causing the co-product prices to decrease during this time (Figure 1).

|

| Figure 1. Four-year price average (2005 to 2008) of dried distillers grains plus solubles. |

Feeding high levels (up to 30 percent) of DDGS is most profitable. Table III summarizes each ration cost. The control diet cost the most per day ($4.73) and the 30 percent DDGS is the cheapest at $4.31 per cow per day. The 15 percent DDGS diet cost is between the control diet and the 30 percent DDGS diet. Including DDGS at 15 percent of the ration saves approximately $0.31 per cow per day, while feeding 30 percent DDGS saves about $0.42 per cow per day in these rations. A 100-head dairy may save $31.00 per day feeding 15 percent DDGS and $42.00 per day feeding 30 percent DDGS. Over one year, the savings in feed cost would be over $15,000. Feeding co-products is economically feasible to reduce ration costs and improve profits. Generally, greater profits occur as co-products are increased in lactating dairy rations.

Summary

The ethanol industry provides co-products that are readily available and useful for lactating dairy cows. Knowing the nutrient composition of the feedstuffs allows for a more accurate and precise estimation of the ration nutrient composition. It is also mindful to maintain adequate particle size in lactating dairy rations for rumen health. Additionally, as co-products are added to the ration, the inclusion level of several feedstuffs, such as forages, may change and the chemical composition of the ration may change. Finally, it is cost effective and cheaper to feed corn milling co-products. As these guidelines are followed, more accurate, precise, and cheaper rations will be formulated.

This publication has been peer reviewed.

Visit the University of Nebraska–Lincoln Extension Publications Web site for more publications.

Index: Dairy

Feeding & Nutrition

Issued February 2010